Proper maintenance of extra large generator sets is crucial to ensure reliable performance and extended service life. These powerful systems require specialized care due to their complex configurations and heavy-duty applications.

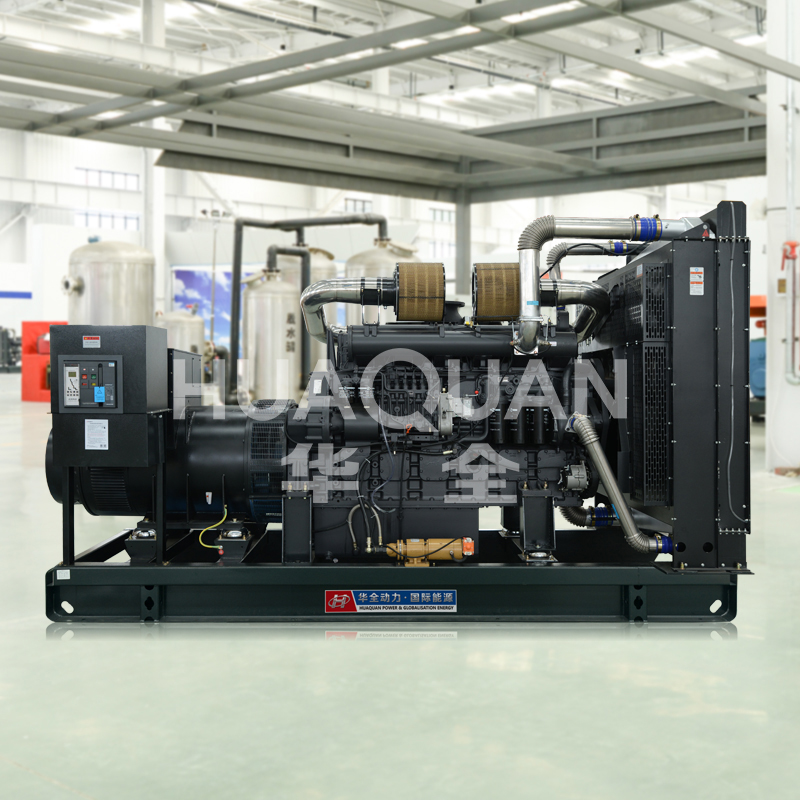

Visual inspections should be conducted daily before operation. Check the extra large generator set for any visible leaks, loose connections, or abnormal wear. The open design allows easy access to major components, but technicians should use proper safety equipment during inspection. Pay special attention to coolant levels, oil condition, and belt tension.

Fluid management forms a critical part of maintenance. Monitor engine oil, coolant, and fuel levels in the extra large generator set with calibrated instruments. Contaminated fluids should be replaced immediately to prevent system damage. Always use manufacturer-recommended grades of oil and coolant for optimal performance.

Battery maintenance requires regular attention in extra large generator sets. Check electrolyte levels (for flooded batteries), clean terminals, and ensure proper charging voltage. Weak batteries are among the most common causes of startup failures in emergency situations.

Air intake systems need frequent cleaning due to the high airflow requirements of extra large generator sets. Inspect and replace air filters as needed, especially in dusty environments. Restricted airflow can significantly reduce efficiency and increase fuel consumption.

Operational testing should be performed regularly, even during standby periods. Run the extra large generator set under appropriate load conditions to verify all systems function correctly. Document performance parameters and compare them against baseline measurements to detect potential issues early.

By implementing these maintenance practices, operators can maximize the reliability and efficiency of their extra large generator set, ensuring it's always ready when needed most.