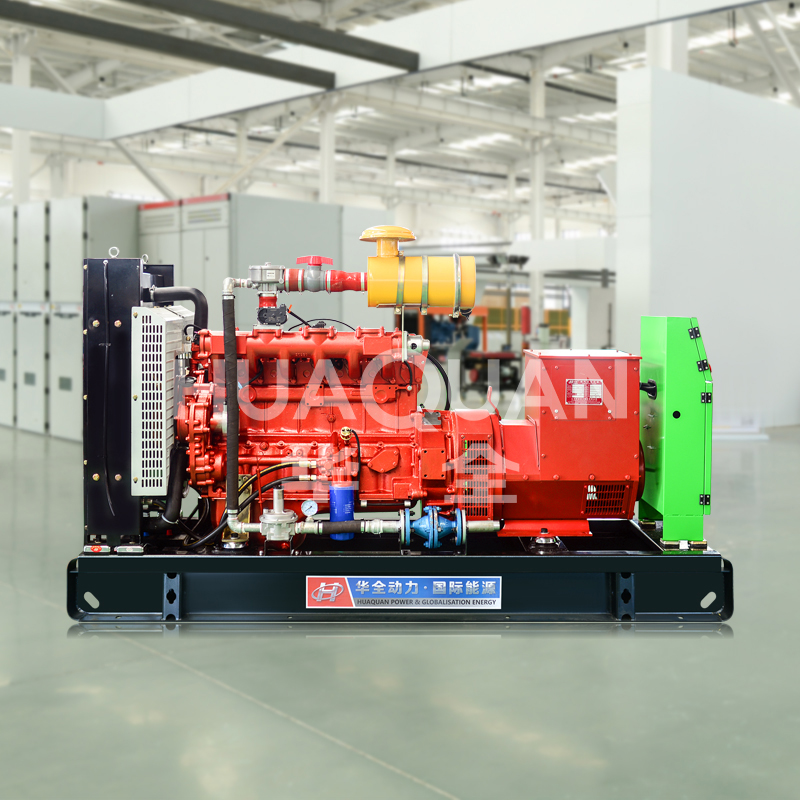

A Gas Generator is a reliable power source for both emergency and routine applications. To ensure safe operation and prolong its service life, proper daily maintenance and usage practices are essential. Below are key considerations for operating a Gas Generator effectively.

1. Pre-Operation Inspection

Before starting the Gas Generator, conduct a thorough visual check. Inspect fuel lines, oil levels, and coolant (if applicable) for leaks or insufficient levels. Ensure the air filter is clean and free of debris to maintain proper airflow. Verify that all connections and cables are secure to prevent electrical hazards.

2. Proper Fuel Management

Always use the recommended fuel type for your Gas Generator to avoid engine damage. Store fuel in approved containers and keep it away from heat sources or open flames. Before refueling, turn off the generator and allow it to cool to minimize fire risks.

3. Ventilation and Placement

Operate the Gas Generator in a well-ventilated area to prevent carbon monoxide buildup. Never use it indoors or in enclosed spaces, as exhaust fumes can be deadly. Place the generator on a stable, level surface to ensure proper lubrication and prevent fuel spillage.

4. Load Management

Avoid overloading the Gas Generator, as this can cause overheating and reduce efficiency. Distribute power usage evenly and prioritize essential appliances. If the generator struggles to maintain consistent power, reduce the load immediately.

5. Routine Maintenance

Regularly check and replace engine oil according to the manufacturer’s guidelines. Clean or replace spark plugs and filters periodically to maintain optimal performance. Keep the exterior free of dust and debris to prevent overheating.

By following these daily practices, users can enhance the safety, efficiency, and longevity of their Gas Generator, ensuring reliable power when needed.

More information about Huaquan Power:https://sinogens.com/